Hi,

This post regarding my 11panel HC-50 Heliocol solar array configuration follows my post about Hayward ECOSTAR SP3400VSP variable speed pump integration with my GoldLine GL-235 solar controller. The system is missing a vacuum breaker and I’d appreciate recommendations regarding proper placement for it for most effective solar array drainage when the pump is off.

My interest in the solar configuration came from a need to determine the most efficient (i.e. heat transfer) flow rate for the Heliocol HC-50 panels. The residential installation manual provides a recommended flow of 5 GPM per panel.

The solar array as shown in the attached pictures is on the far side of the roof ridgeline from the pool pump. The first HC-50 panel is fed by a 2 inch pipe approx. 46 feet long which crosses a 26 ft. high roof ridge. The 11 panels are arranged in a split series array (i.e. 6 panels feed a 2 inch line connected to the next 5 panels) as recommended in the Heliocol Residential Installation Manual which limits the maximum number of HC-50 panel in series to 8. The return pipe from the far end of the array to the pump is approximately 84 feet. The pool equipment consists of a Hayward DE 7220 filter and Intermatic clocks controlling AquaRite chlorine generator, Goldline GL-235 solar controller, auto fill system, and ECOSTAR SP3400VSP pump.

A Heliocol rep replied to my request for optimum flow rate information stating “5gpm / per collector is a minimum recommended flow rate. The allowable flow rate is up to 10 gpm per panel. So your calculation of 30 gpm for the larger array of 6 if placed in series is correct.“ For my pool plumbing system with the ECOSTAR SP3400VSP installed the following data points were obtained from the ECOSTAR readout and a flow meter installed about 6 feet above the pool deck:

30 GPM at 1850 RPM/342 watts/filter 10 psi. 25,000 gal pool turnover is approx. 14 hrs

40 GPM at 2250 RPM/580 watts/ filter 14 psi. Pool turnover approx. 10.5 hrs

50 GPM at 2850 RPM/1138 watts/filter 20 psi. Pool turnover approx. 8.5 hrs

60 GPM at 3200 RPM/1600 watts/filter 24 psi.at Pool turnover approx. 7 hrs

Since I was unable to get any specific information from Heliocol regarding heat transfer variance between 5 GPM and 10 GPM through a panel I settled on 40 GPM to take into account pool turnover time.

By this time I’d read through the Heliocol installation manual several times and been on the roof to look over my solar array. I noted for my solar system configuration as shown in the attached pictures that:

1. there were no drains installed in the array as required for the 12 year Heliocol warranty for freeze damage

2. There was no check valve between the filter and the 3 way valve.

3. there was no vacuum breaker installed

Item 1 was never installed. Due to panel location on the far side of the roof ridge it looks like 3 drains will need to be installed at the low points of the arrays shown in the picture. Item 2 check valve was initially installed correctly but my pool remodeler changed the check valve location to its current location. Due to space constraints I will add a Jandy 7305 check valve with 2.5 inch connector (or possibly Jandy 7307 with 2.5/2.0 bushing) to the existing 3 way valve and a new Hayward SP0410X5025 backwash valve. Then I will remove the check valve flapper above the 3 way valve.

Which brings me to Item 3, the missing vacuum breaker. A vacuum breaker was not seen on the vertical feed pipe from pictures I took at the time the Heliocol system was installed. A vacuum breaker may have been installed on the roof originally, but when the solar array was moved from the south facing roof to the west facing roof (by the same installation company) to make room for the PV solar array it could have been removed. In any event, Heliocol instructions page 19 step 6 recommend HC-121A (now HC-121B) vacuum breaker placement “about 4 feet vertically above the filter…” Online forum discussions at http://www.troublefreepool.com/ and company web sites such as Hot Sun Industries (especially Hot Sun Industries videos/engineering descriptions at http://www.h2otsun.com/videos.html) indicate that the Heliocol vacuum breaker placement recommendation by Heliocol may not be the most effective vacuum breaker location in my case.

My sense is that the vacuum breaker should be placed just before the cold water feed line enters the first HC-50 panel. This would allow maximum drainage of the HC-50 panels by gravity/siphon through the solar return line when the pump is turned off.

***Would appreciate any thoughts/recommendation regarding most appropriate vacuum breaker placement for my system.

But then there is also the cold water feed line drain to consider. Its drainage is through the 3 way valve back to the pool. Some online forums recommend a 1/8 inch hole drilled into the 3 way valve face to allow for gradual draining when the pump is off.

***Thoughts/recommendations on this aspect would also be appreciated.

Finally, I read that high temperature can damage a solar system and PVC piping connecting it. On a recent 100 + deg day here in El Cajon, CA the solar system had been off for several hours with the GL-235 set to 85 deg and the aquarite water temp sensor showing 89 deg. I saw 140 deg at the temp sensor I installed on the return pipe when I put the GL-235 switch to test and engaged the solar array (note: at this high temp the Aqaurite system seems to go to Hi salt and stops providing temperature). The GL-235 manual states:

“In the “AUTO” position, the GL-235 will heat the pool or spa (rotate valve to solar loop) when the collector (solar) sensor temperature [my note…air temp sensor] is higher than the pool/spa sensor temperature [my note…feed water temp sensor] by 4ºF or more AND the pool/spa temperature is less than the high limit setting. The GL-235 will stop heating (return valve to pool loop) when the two sensor temperatures get to within 1.5ºF OR the pool/spa sensor is above the high limit setting. “

Since the pool pump is operating with the 3 way valve in the solar off position I assume the solar array can’t drain past the return line check valve held closed by the pump pressure. So my impression is that the 140 deg high temp I saw was normal.

***Am I correct?

Looking forward to your comments!

(will ask Pool Forum Administrator to add images)

Hayward DE Filter manual. Issuu company logo. Similar to sand filters, when D.E. Filters become dirty, they are cleaned either by backwashing, or regenerating and draining the clogged D.E. To the 'waste' line. To restore filtration, a fresh 'charge' of D.E. Is added to the filter. For sparkling, clean pools; step up to Hayward D.E. SP0410X5025: Slide Valve Assembly. 2' SKT: 1: NOTES:.Compatible only with DEX2421JKIT clamp system for Hayward Pro-Grid D.E. And SwimClear cartridge filters.Assembled set of filter elements, manifold flex air relief, retainer rod and element locator.

Sp0410x5025

Hayward Slide Valve 2' SP410X - INYOpools.com has the largest selection of swimming pool and spa replacement parts with over 70,000 parts in stock. Order today and save! Hayward Pro-Grid Slide Valve Assembly – 2' SKT SP0410X5025. VERTICAL GRID D.E. FILTER SERIES REPLACEMENT PARTS.

Sp0410x5025 Slide Valve

Hi,

This post regarding my 11panel HC-50 Heliocol solar array configuration follows my post about Hayward ECOSTAR SP3400VSP variable speed pump integration with my GoldLine GL-235 solar controller. The system is missing a vacuum breaker and I’d appreciate recommendations regarding proper placement for it for most effective solar array drainage when the pump is off.

My interest in the solar configuration came from a need to determine the most efficient (i.e. heat transfer) flow rate for the Heliocol HC-50 panels. The residential installation manual provides a recommended flow of 5 GPM per panel.

The solar array as shown in the attached pictures is on the far side of the roof ridgeline from the pool pump. The first HC-50 panel is fed by a 2 inch pipe approx. 46 feet long which crosses a 26 ft. high roof ridge. The 11 panels are arranged in a split series array (i.e. 6 panels feed a 2 inch line connected to the next 5 panels) as recommended in the Heliocol Residential Installation Manual which limits the maximum number of HC-50 panel in series to 8. The return pipe from the far end of the array to the pump is approximately 84 feet. The pool equipment consists of a Hayward DE 7220 filter and Intermatic clocks controlling AquaRite chlorine generator, Goldline GL-235 solar controller, auto fill system, and ECOSTAR SP3400VSP pump.

A Heliocol rep replied to my request for optimum flow rate information stating “5gpm / per collector is a minimum recommended flow rate. The allowable flow rate is up to 10 gpm per panel. So your calculation of 30 gpm for the larger array of 6 if placed in series is correct.“ For my pool plumbing system with the ECOSTAR SP3400VSP installed the following data points were obtained from the ECOSTAR readout and a flow meter installed about 6 feet above the pool deck:

30 GPM at 1850 RPM/342 watts/filter 10 psi. 25,000 gal pool turnover is approx. 14 hrs

40 GPM at 2250 RPM/580 watts/ filter 14 psi. Pool turnover approx. 10.5 hrs

50 GPM at 2850 RPM/1138 watts/filter 20 psi. Pool turnover approx. 8.5 hrs

60 GPM at 3200 RPM/1600 watts/filter 24 psi.at Pool turnover approx. 7 hrs

Since I was unable to get any specific information from Heliocol regarding heat transfer variance between 5 GPM and 10 GPM through a panel I settled on 40 GPM to take into account pool turnover time.

By this time I’d read through the Heliocol installation manual several times and been on the roof to look over my solar array. I noted for my solar system configuration as shown in the attached pictures that:

1. there were no drains installed in the array as required for the 12 year Heliocol warranty for freeze damage

2. There was no check valve between the filter and the 3 way valve.

3. there was no vacuum breaker installed

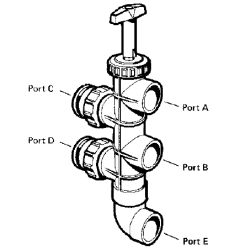

Item 1 was never installed. Due to panel location on the far side of the roof ridge it looks like 3 drains will need to be installed at the low points of the arrays shown in the picture. Item 2 check valve was initially installed correctly but my pool remodeler changed the check valve location to its current location. Due to space constraints I will add a Jandy 7305 check valve with 2.5 inch connector (or possibly Jandy 7307 with 2.5/2.0 bushing) to the existing 3 way valve and a new Hayward SP0410X5025 backwash valve. Then I will remove the check valve flapper above the 3 way valve.

Which brings me to Item 3, the missing vacuum breaker. A vacuum breaker was not seen on the vertical feed pipe from pictures I took at the time the Heliocol system was installed. A vacuum breaker may have been installed on the roof originally, but when the solar array was moved from the south facing roof to the west facing roof (by the same installation company) to make room for the PV solar array it could have been removed. In any event, Heliocol instructions page 19 step 6 recommend HC-121A (now HC-121B) vacuum breaker placement “about 4 feet vertically above the filter…” Online forum discussions at http://www.troublefreepool.com/ and company web sites such as Hot Sun Industries (especially Hot Sun Industries videos/engineering descriptions at http://www.h2otsun.com/videos.html) indicate that the Heliocol vacuum breaker placement recommendation by Heliocol may not be the most effective vacuum breaker location in my case.

My sense is that the vacuum breaker should be placed just before the cold water feed line enters the first HC-50 panel. This would allow maximum drainage of the HC-50 panels by gravity/siphon through the solar return line when the pump is turned off.

***Would appreciate any thoughts/recommendation regarding most appropriate vacuum breaker placement for my system.

But then there is also the cold water feed line drain to consider. Its drainage is through the 3 way valve back to the pool. Some online forums recommend a 1/8 inch hole drilled into the 3 way valve face to allow for gradual draining when the pump is off.

***Thoughts/recommendations on this aspect would also be appreciated.

Finally, I read that high temperature can damage a solar system and PVC piping connecting it. On a recent 100 + deg day here in El Cajon, CA the solar system had been off for several hours with the GL-235 set to 85 deg and the aquarite water temp sensor showing 89 deg. I saw 140 deg at the temp sensor I installed on the return pipe when I put the GL-235 switch to test and engaged the solar array (note: at this high temp the Aqaurite system seems to go to Hi salt and stops providing temperature). The GL-235 manual states:

“In the “AUTO” position, the GL-235 will heat the pool or spa (rotate valve to solar loop) when the collector (solar) sensor temperature [my note…air temp sensor] is higher than the pool/spa sensor temperature [my note…feed water temp sensor] by 4ºF or more AND the pool/spa temperature is less than the high limit setting. The GL-235 will stop heating (return valve to pool loop) when the two sensor temperatures get to within 1.5ºF OR the pool/spa sensor is above the high limit setting. “

Since the pool pump is operating with the 3 way valve in the solar off position I assume the solar array can’t drain past the return line check valve held closed by the pump pressure. So my impression is that the 140 deg high temp I saw was normal.

***Am I correct?

Looking forward to your comments!

(will ask Pool Forum Administrator to add images)